O/W or W/O?

Whether you are in the cosmetics business or not, you will be familiar with the basic physical fact that oil/fat and water cannot mix. In the cosmetic world, however, we need to keep these two ingredients together, and that's what emulsifiers are for.

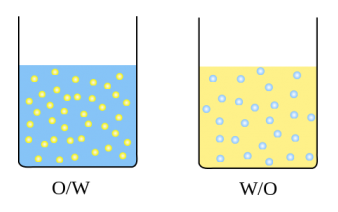

When oil and water are mixed together by adding an emulsifier, two types of emulsions are created:

- oilin Water ( O/W )

The aqueous phase can be water or any hydrophilic liquid (e.g., hydrolates, floral water) and the oil the oil phase, in turn, may consist of a lipophilic substance or a mixture of several (e.g. oils, fatty esters or fatty alcohols). At the same time, in both types, the aqueous phase is in the ratio of 60-80%.

What is the difference between them?

When is it better to use an O/W and when a W/O emulsion?

Let's characterize these two types in more detail.

Oil-in-water O/W emulsion

In this emulsion, the oil is dispersed in the aqueous phase. They are mainly used in cosmetic products with a moisturizing effect (these emulsions are easy to spread, they are lighter because the aqueous phase is the outer phase). They are also used in rinse-off products because they are easy to wash out. As for the use of emulsifier, they require the use of more emulsifiers.

O/W emulsions are more susceptible to microbiological activity and therefore need to be properly preserved.

O/W emulsions exhibit electrical conductivity.

These emulsions can be thickened ( viscosity increased) by adding natural thickeners such as xanthan gum, konjac powder, carrageenan, etc.

Water-in-oil emulsion W/O

In this emulsion, water droplets are dispersed in the oil. These emulsions are used in products designed for dry and sensitive skin, but also in skin care products during the winter season (they can be greasy, heavier, because the oil phase is the outer phase). They are most commonly used in creams, sunscreens and most make-ups (because W/O emulsions are water resistant, some even completely water resistant). The production of W/O emulsions is more difficult than that of O/W emulsions. You only need one emulsifier to create this emulsion, but there are a limited number of suitable emulsifiers.

Since the aqueous phase in a W/O emulsion is actually hidden in the oil phase, it is easier to preserve and less susceptible to microbiological contamination (we will discuss preservatives and product preservation in more detail).

W/O emulsion does not exhibit conductivity.

The viscosity of W/O emulsions is not affected by thickeners. Increase the viscosity by using waxes.