Production of soap by hot process

The process of making hot soap is very similar to cold process, except that it takes place at an elevated temperature. After the saponification process, the soap immediately has the desired pH. Therefore, a shorter time is required for maturation before use. A minor disadvantage is colouring, as the resulting mass is quite dense and hardens quickly, we cannot create such nice patterns as in the cold process.

Procedure:

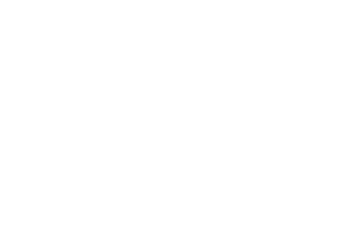

1. Prepare all the necessary ingredients, in our case, distilled water and sodium hydroxide (both ingredients can be purchased at a regular drugstore), olive oil, coconut oil, castor oil, essential oil- lavender, dried lavender, pH papers, thermometer, protective equipment- gloves, face mask, goggles

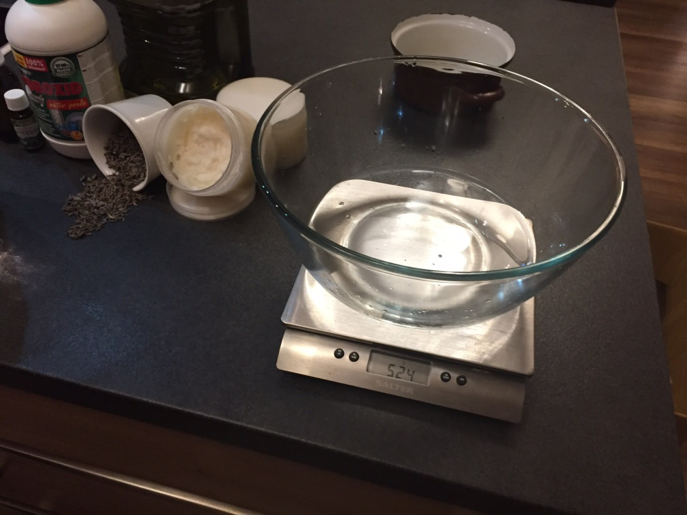

2.put on protective equipment before production. First prepare the sodium hydroxide solution. Weigh out the necessary amount of distilled water.

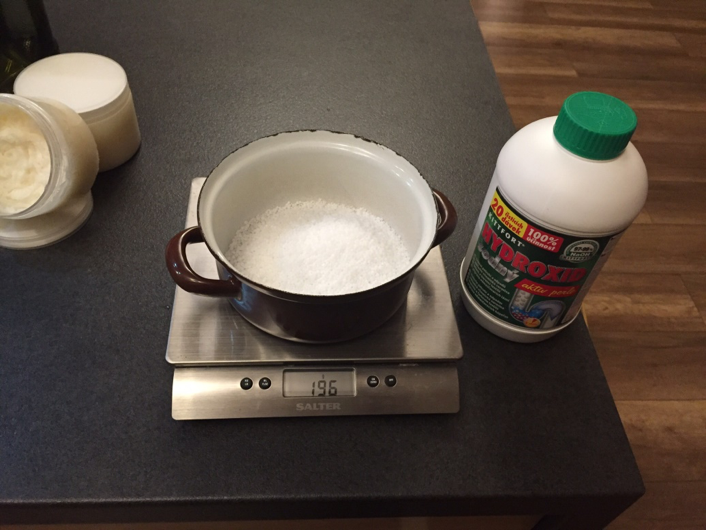

3.in the next container, weigh the necessary amount of sodium hydroxide

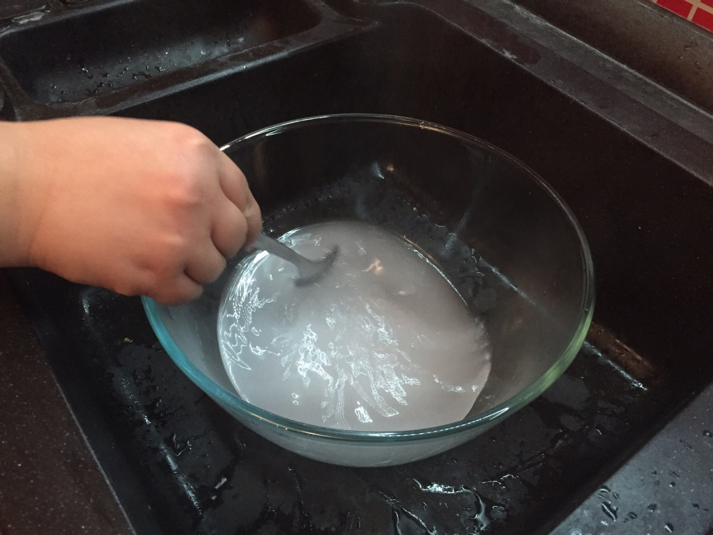

4.in the sink, pour the hydroxide into the distilled water, being careful to ALWAYS pour the hydroxide into the water, NOT INTO the water. Stir the hydroxide, do not breathe the vapor. It is best to prepare the solution in a ventilated area or with a window open. The resulting hydroxide has a high temperature, so let it cool to about 35°C

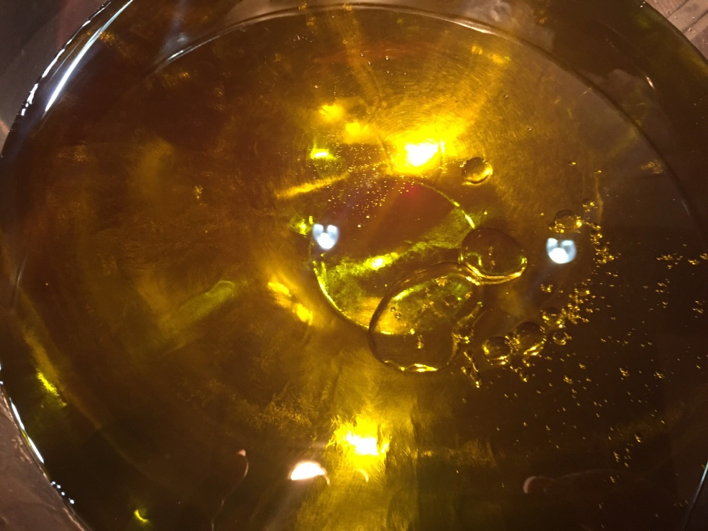

5.while the hydroxide is cooling, prepare the oil mixture. Weigh out the necessary amount of olive oil, add coconut oil and castor oil. We use a container that is suitable for a water bath (in our case a metal bowl)

6.place the weighed oils in the water bath, let the solid oils dissolve. The oils should reach the same temperature as the hydroxide solution.

7.slowly pour the hydroxide solution into the oil mixture, mixing it with a spatula first.

8.when the oils and hydroxide are mixed, use an immersion blender to combine them. Mix until a 'trace' is formed.

9.cover the mixture in the trace with foil and leave it on the water bath over a low heat.

10.check the mixture continuously, approximately every 15 minutes. Gradually the saponification process takes place. Stir the soap so that it does not boil.

11.gradually the whole mixture will saponify - the soap is almost ready. Allow the saponification process to continue until the pH of the mixture is about 8. Measure the pH by taking a small amount of the mixture, dipping a pH strip into it and comparing it to the pH scale on the packaging of the pH strips.

12.when the saponification process is complete, remove the soap from the heat source. Next comes the addition of essential oils and, in our case, dried herbs. Essential oils have different evaporation temperatures, so it is important that the soap is at a lower temperature than the evaporation temperature of the essential oil. Add essential oil, dried herbs.

13.pour the soap into a baking tray lined with baking paper, we used dried lavender flowers for decoration. Cover the finished soap and leave to rest for 24 hours.

14.after 24 hours, remove the soap from the mould and cut into desired pieces. Leave the soap to dry for about 2 weeks to evaporate the residual water.